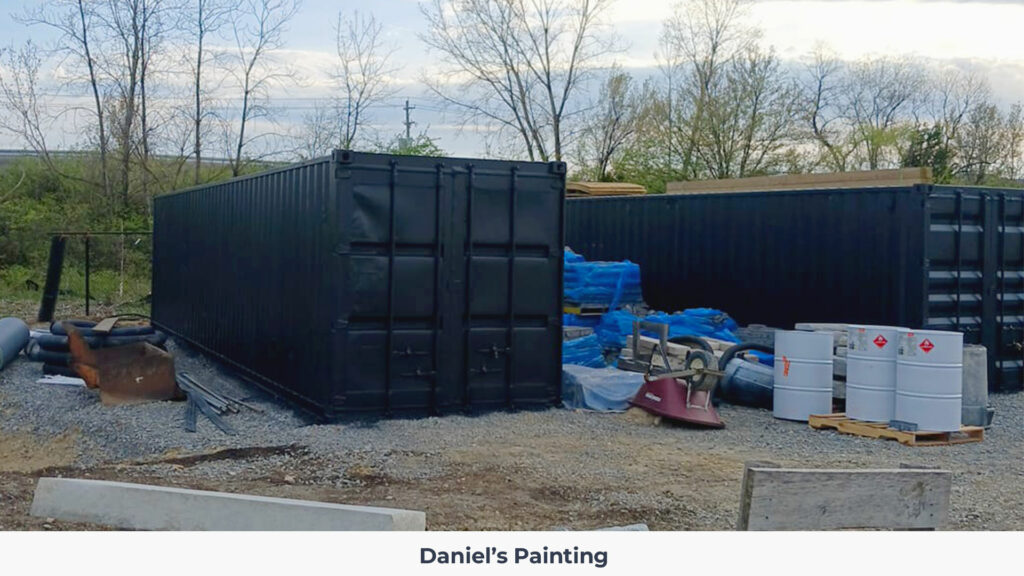

Some paint jobs are more than “a coat of color.” They’re a promise—the promise that every inch—every rivet, seam, hinge, and corner—will get the same care as the most visible surfaces. At Daniels Painting, that promise is our standard. And nothing shows it better than a recent project: turning a weather-worn shipping container into a clean, protected, satin-black workhorse.

Why tell the story of a container? Because it’s the perfect stress test. Metal. Rust. UV exposure. Constant temperature swings in Ohio. If we can make a container look sharp and last longer outdoors, imagine what that level of detail can do for your home or business.

The Challenge: Weather, Wear, and a Lot of Metal

This container had spent several Ohio seasons out in the elements—sun, rain, and freeze–thaw cycles. The original finish had faded. Rust was creeping along seams and around the hardware. In the wrong hands, this is where people try to “hide” problems under paint.

We don’t hide problems. We fix them.

Our goals were twofold:

- Restore the surface so the new coating would bond the way it’s designed to.

- Elevate the look with a smooth, uniform finish that made the unit look new—without sacrificing durability.

Our Approach: Details First, Paint Second

Great results start long before the sprayer turns on. This is the Daniels Painting process we used on this container—and the process we bring to every metal restoration in Ohio.

1) Site Prep & Protection

We prepared the area to keep dust and overspray off nearby materials. That meant masking the slab, protecting surrounding equipment, and planning hose runs to keep walkways safe. (If you’ve ever tripped over a hose, you know why this matters.)

Why it matters: Clean edges and a tidy site are signs of respect—for your property and for the finish we’re about to apply.

2) Deep Clean & Degrease

Metal holds on to oils and residue. We performed a thorough wash and degrease so contaminants wouldn’t interfere with adhesion. Only after a full dry-down did we move forward.

Why it matters: Paint bonds to clean surfaces. Skipping this step is the fastest way to a short-lived job.

3) Mechanical Prep: Rust Removal & Profiling

We attacked corrosion at the source—hand and power-tool cleaning at seams and hinges, removing oxidation, and creating the right surface profile for primer.

Why it matters: Rust never sleeps. If you don’t disrupt it and seal it, it returns—and it lifts the paint with it.

4) Spot Repair & Feathering

We repaired minor dings and feathered transitions so the finished look would be smooth from end to end. On corrugated metal, poor feathering shows up as waves and ridges in the final sheen. We don’t leave those.

Why it matters: A durable finish can still look uneven if the substrate isn’t blended. Prep equals beauty.

5) Professional Spray Application

With masking tight and the weather cooperating, we sprayed a high-quality satin-black topcoat. Consistent distance, pass speed, and overlap produced an even film build—no stripes and no “tiger striping.”

Why it matters: Spraying isn’t about moving fast—it’s about moving evenly. That’s how you get that deep, uniform color that looks great up close and from the street.

6) Final Inspection

We removed masking only when it was safe, then performed a detailed inspection. The coating needs time to cure, and we advise clients on handling and reuse based on temperature and humidity.

Why it matters: The last 5% of the job protects the first 95%.

Results You Can See (and Feel)

Before: Oxidized panels, corrosion along seams, sun-bleached finish.

After: Uniform satin black from hinge to hinge. Crisp edge along the slab. Clean, functional hardware. No thin spots. No runs.

Beyond aesthetics, the container is now better protected against unpredictable weather. That protection buys time—time before the next maintenance cycle, and time your crew can spend using the container instead of fixing it.

Why These Details Matter on Your Project

Whether you’re restoring a metal container, repainting aluminum siding, or refreshing a commercial façade, prep is performance. Here’s how our detail-driven approach pays off:

- Longer service life: Proper cleaning, rust removal, and priming prevent peeling and blistering.

- Lower total cost: When a coating system lasts, you repaint less often.

- Stronger curb appeal: Precise masking, even sheen, and uniform color elevate everything around the painted surface.

It’s not glamorous—it’s professional. And it’s how we protect your investment.

We handle interior and exterior work, residential and commercial projects, and specialty surfaces like metal, stucco, wood trim, aluminum siding, decks, and fences. If it needs prep, protection, and a beautiful finish, we’re in our element.

FAQs

Can you match specific colors or sheens?

Yes. We can match brand colors or recommend finishes (satin, semi-gloss, etc.) based on durability and aesthetics.

Do you only restore containers?

No. A container is just one example. We routinely prep and paint metal railings, doors, aluminum siding, and commercial exteriors—along with full interior and exterior repaints for homes and businesses.

What This Project Says About Us

Anyone can “paint.” Not everyone slows down for the steps that make paint last. Our clients choose Daniels Painting for exactly that—trust built on process, and professionalism you can see in every line we cut and every surface we finish.

If you’re in Ohio and want a team that treats your property like it’s our own—whether it’s a container, a storefront, or your living room—you’ll feel right at home with us.